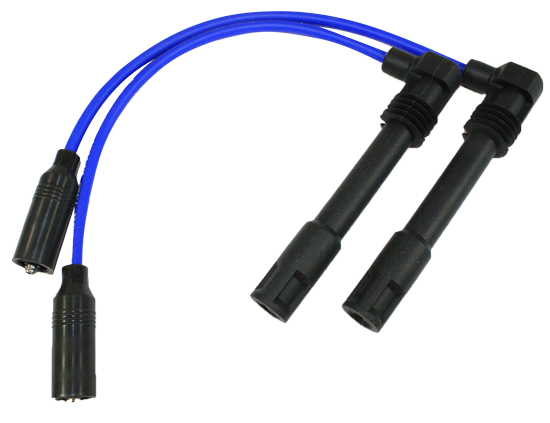

Key Features of High-Tech Ignition Leads

Super Low Resistance:

- 50 ohm/ft: This ultra-low resistance ensures that the electrical current flows with minimal impedance, allowing for a more robust and consistent spark. This improvement is crucial for maintaining engine efficiency and reducing misfires.

Advanced Core Materials:

- Aramid Inner Core: Known for its exceptional strength and heat resistance, the aramid inner core provides a durable foundation for the ignition lead. This core is designed to withstand the harsh conditions within the engine bay, including high temperatures and vibrations.

Spiral-Wound Conductor:

- Full Spark Delivery: The spiral-wound conductor ensures maximum spark delivery by maintaining a strong and stable connection between the ignition coil and the spark plug. This design also helps in suppressing electromagnetic interference (EMI), which can cause disruptions in electronic systems.

Dielectric Barrier:

- Prevents Current Leakage: A dielectric barrier is incorporated to prevent any current leakage, ensuring that all the electrical energy is directed towards generating a strong spark. This barrier enhances the overall efficiency of the ignition system.

Braided Fiberglass Layer:

- Strength and Flexibility: To further enhance durability, the ignition leads are reinforced with a braided fiberglass layer. This layer provides additional strength while maintaining flexibility, allowing the leads to be easily routed through the engine bay without the risk of damage or breakage.

The Benefits for Technicians and Drivers

For technicians, the introduction of these high-tech ignition leads means easier installations and fewer callbacks for ignition-related issues. The improved durability and performance of these leads reduce the need for frequent replacements and maintenance, saving time and costs.

For drivers, the benefits are equally significant. High-tech ignition leads contribute to smoother engine operation, improved fuel efficiency, and reduced emissions. With consistent and reliable spark delivery, drivers can expect better acceleration and overall vehicle performance.

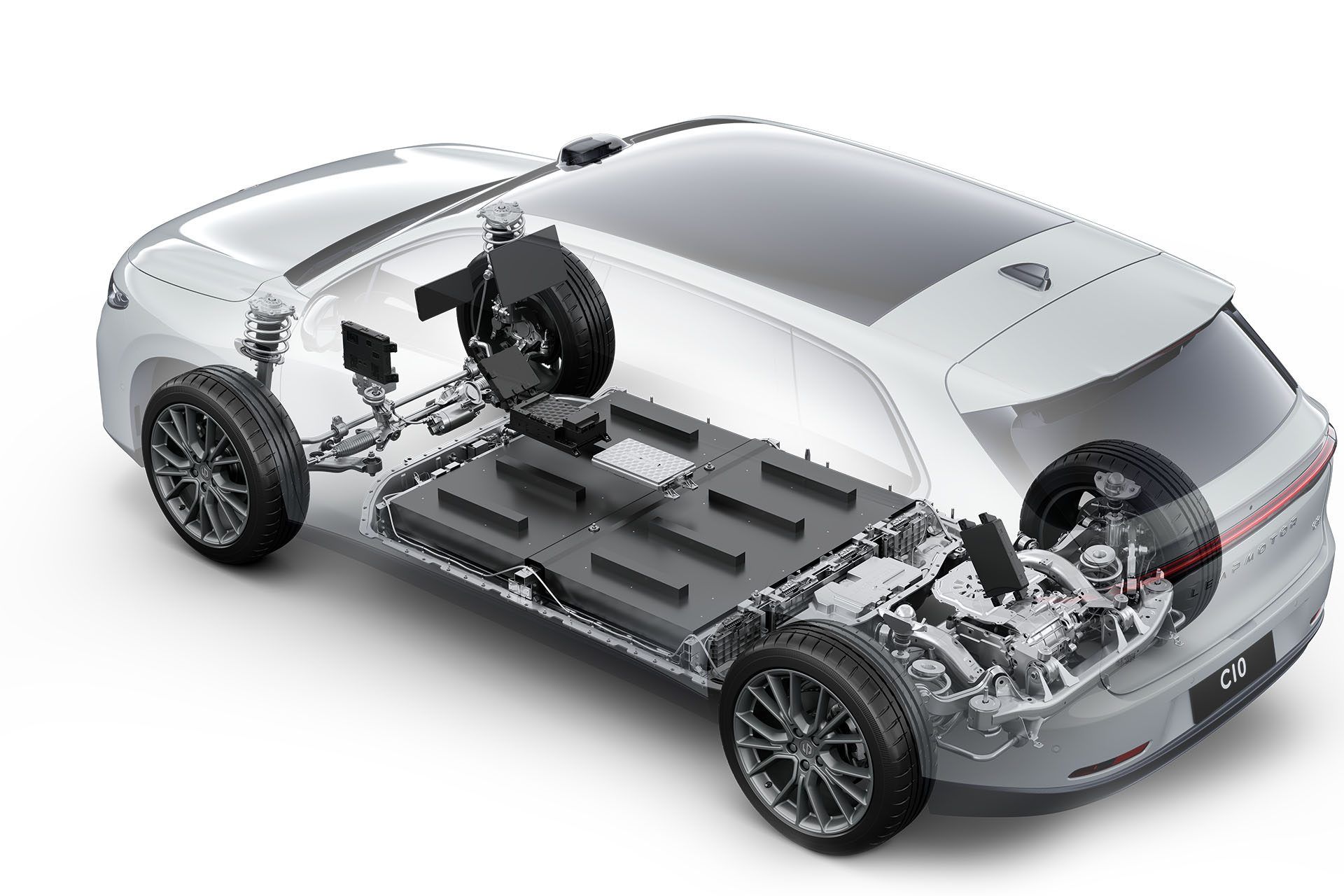

Embracing the Future of Automotive Technology

As automotive technology continues to advance, components like ignition leads are becoming more sophisticated, incorporating materials and designs that were once reserved for high-performance and specialized applications. The adoption of these high-tech ignition leads in everyday vehicles highlights the industry's commitment to enhancing reliability, efficiency, and performance.

For technicians, staying updated with these advancements is essential. Understanding the features and benefits of modern ignition leads allows technicians to make informed recommendations and provide superior service to their customers.

Conclusion

The evolution of the humble ignition lead into a high-tech component underscores the rapid advancements in automotive technology. With features like super low resistance, aramid inner cores, spiral-wound conductors, dielectric barriers, and braided fiberglass layers, these ignition leads represent the cutting edge of automotive innovation. For technicians and drivers alike, these enhancements promise improved performance, reliability, and efficiency, marking a new era in vehicle maintenance and operation.