Smart Lubrication Systems (SLS)

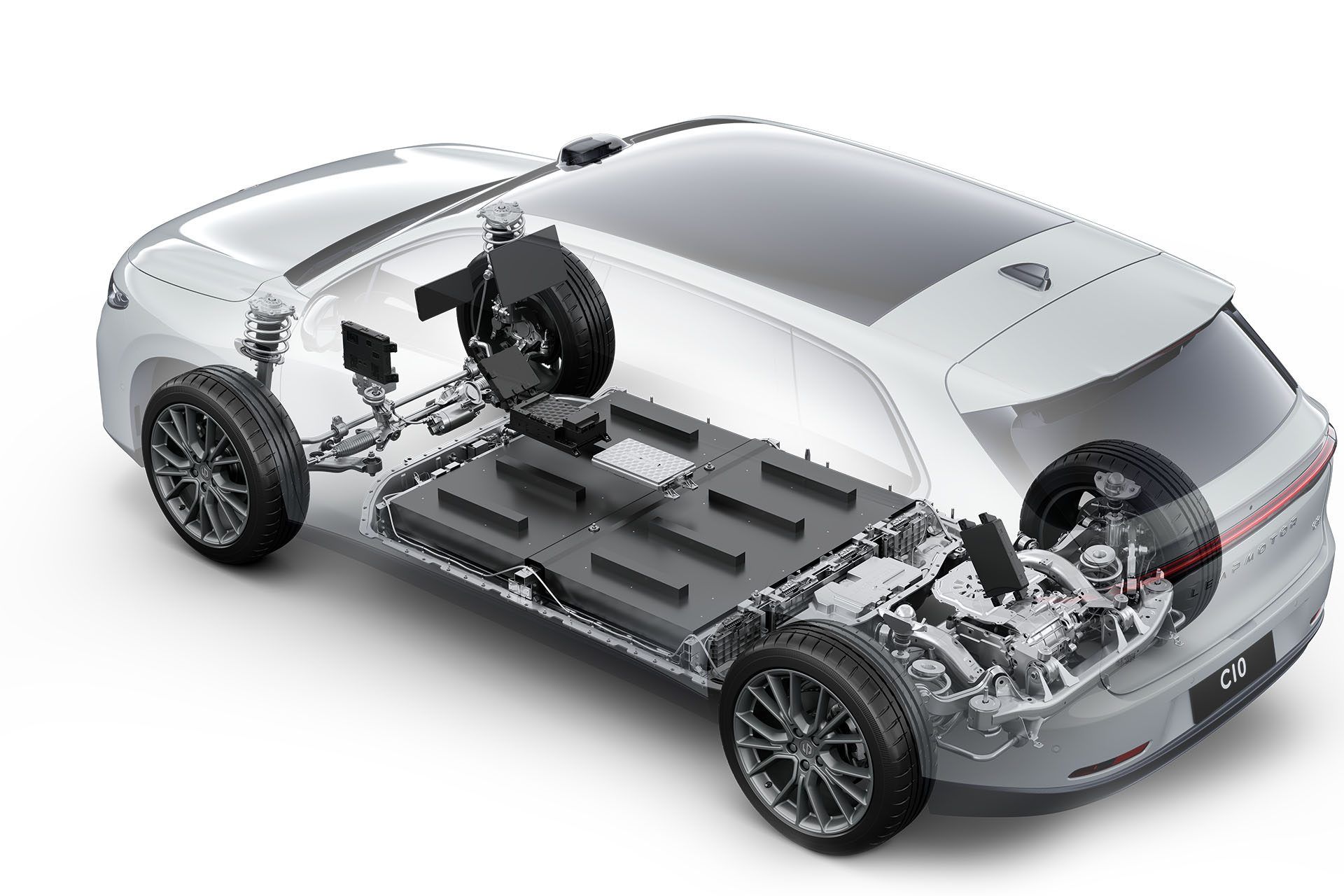

Smart Lubrication Systems (SLS) employ a combination of sensors, actuators, and control algorithms to optimize lubricant usage in machinery, particularly in automotive engines.

Here's how they typically work:

Sensors and Monitoring: Smart lubrication systems are equipped with various sensors to monitor operating conditions such as temperature, pressure, vibration, and lubricant quality. These sensors continuously gather data about the condition of the lubricant and the components it's protecting.

Data Processing and Analysis: The data collected by sensors are processed by onboard control units or transmitted to a centralized control system. Advanced algorithms analyze the data to determine factors such as lubricant viscosity, contamination levels, and wear rates of engine components.

Dynamic Adjustment: Based on the real-time analysis of operating conditions, smart lubrication systems can dynamically adjust lubricant properties, such as viscosity or additives concentration, to optimize performance and protection. For example, the system may adjust the flow rate of oil to specific engine components based on their temperature and load.

Predictive Maintenance: Smart lubrication systems can also predict potential issues such as oil degradation, component wear, or impending lubricant failure. By monitoring trends over time, these systems can anticipate maintenance needs and schedule servicing before problems occur, minimizing downtime and reducing the risk of costly repairs.

Integration with Vehicle Systems: Smart lubrication systems are often integrated with the vehicle's onboard computer network, allowing seamless communication with other vehicle systems such as the engine management system or transmission control unit. This integration enables coordinated operation and optimization of all vehicle subsystems for improved overall efficiency.

User Interface and Feedback: Many smart lubrication systems provide feedback to vehicle operators or maintenance personnel through dashboard displays, warning lights, or diagnostic reports. This feedback informs users about the health of the lubrication system and any actions needed to maintain optimal performance.

Remote Monitoring and Telematics: In some cases, smart lubrication systems may be equipped with remote monitoring capabilities, allowing real-time data transmission to a central monitoring facility or cloud-based platform. This enables fleet managers or maintenance teams to remotely monitor lubrication system performance across multiple vehicles and take proactive maintenance actions as needed.

Overall, smart lubrication systems leverage advanced sensing, control, and communication technologies to optimize lubricant usage, prolong equipment life, minimize energy losses, and reduce emissions. By ensuring that the right lubricant is used at the right time and in the right amount, these systems contribute to improved efficiency, reliability, and sustainability in automotive and industrial applications.