The Transformative Power of 3D Printing

In the ever-evolving landscape of the automotive industry, technology continues to play a pivotal role in driving innovation. One such transformative technology that has gained significant traction in recent years is 3D printing, also known as additive manufacturing. This groundbreaking method is reshaping the manufacturing processes within the automotive sector, offering unprecedented advantages in terms of efficiency, customization, and performance.

Rapid Prototyping and Accelerated Design

One of the primary benefits of 3D printing in the automotive industry lies in its ability to facilitate rapid prototyping. Traditional manufacturing processes often involve time-consuming steps in prototyping, leading to prolonged design and testing phases. 3D printing changes this paradigm by allowing manufacturers to create prototypes quickly and efficiently.

This accelerated prototyping not only reduces time-to-market but also provides designers and engineers with the flexibility to iterate and refine designs with ease. The result is a more streamlined and agile development process, enabling automotive companies to respond rapidly to market demands and stay ahead of the competition.

Customized Spare Parts On-Demand

The automotive industry is notorious for the challenges associated with spare parts management. 3D printing revolutionizes this aspect by offering manufacturers the capability to produce spare parts on-demand and to exact specifications. This on-the-fly production of spare parts eliminates the need for large inventories of pre-manufactured components and reduces the costs associated with storage and logistics.

With 3D printing, manufacturers can respond swiftly to specific repair or replacement needs, enhancing overall efficiency in maintenance and repair operations. This not only saves time but also contributes to cost savings and a more sustainable approach to inventory management.

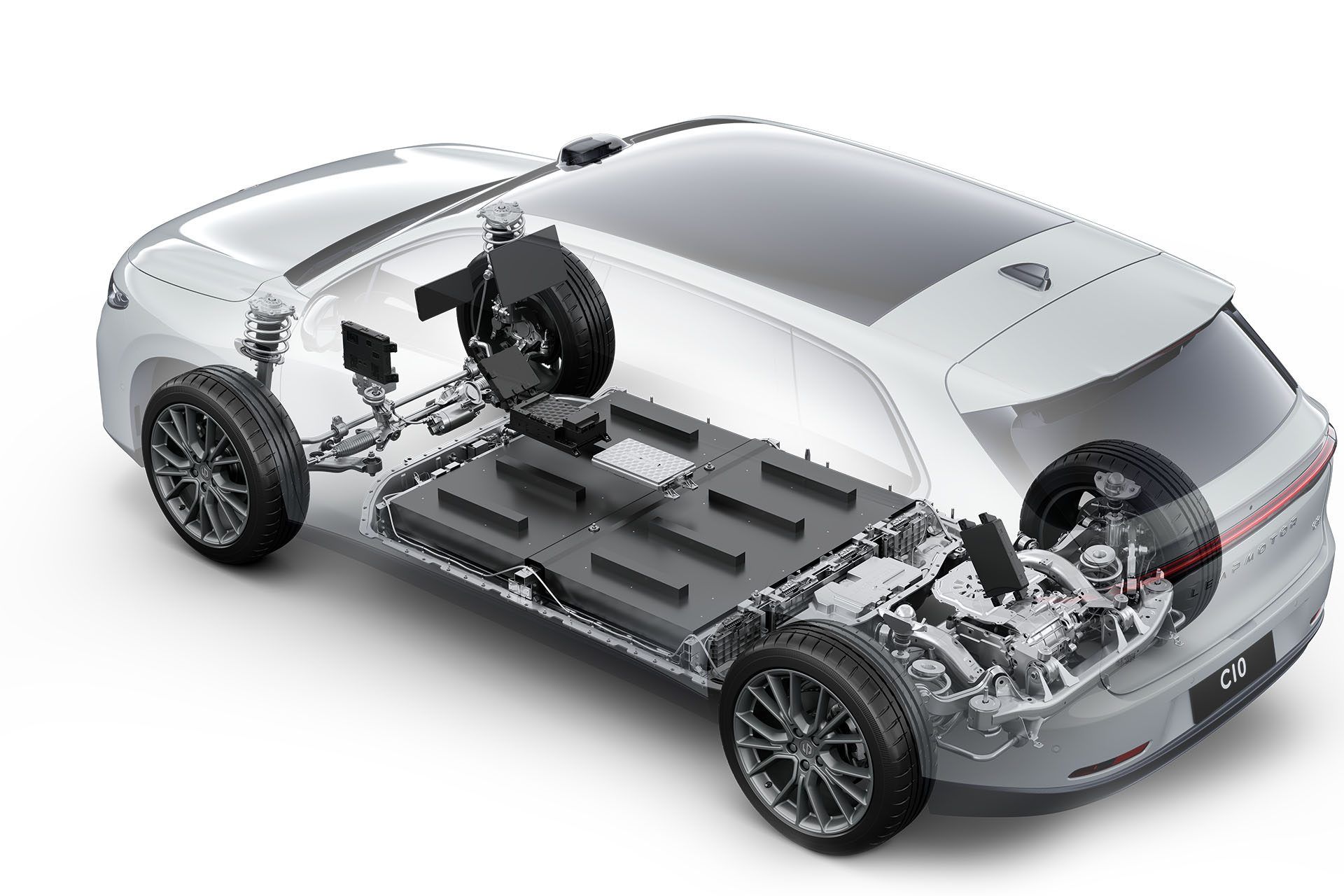

Lightweight, Durable, and Strong Automotive Parts

Additive manufacturing of composite materials is reshaping the landscape of automotive components. The use of 3D printing allows for the creation of parts that are not only lightweight but also exhibit enhanced durability and strength. This has significant implications for the design and performance of modern cars. Lightweight automotive parts contribute to fuel efficiency, making vehicles more environmentally friendly and cost-effective. The strength and durability of 3D-printed components also lead to safer and more resilient vehicles. As a result, automotive manufacturers can produce cars that are not only more efficient but also boast improved performance and safety features.

The integration of 3D printing into the automotive industry represents a paradigm shift in manufacturing processes. From rapid prototyping to on-demand production of spare parts and the creation of lightweight, durable components, 3D printing is enhancing efficiency and pushing the boundaries of what is possible in automotive design. As this technology continues to advance, we can expect to witness even greater innovation, ultimately shaping a future where automotive manufacturing is more agile, sustainable, and responsive to the evolving needs of the market.