The automotive industry has always been at the forefront of innovation, and nowhere is this more evident than in motorsport. With increasing pressure to reduce carbon emissions while maintaining the high-performance standards of internal combustion engines, one technology that has been gaining traction is synthetic fuels, commonly referred to as e-fuels. While electric vehicles dominate public discourse, e-fuels present a viable alternative that retains the internal combustion engine while dramatically reducing its environmental impact.

E-Fuels and Their Impact on the Industry

An Article by IAME CEO Peter Blanshard

E-fuels are produced using a process that captures and repurposes carbon dioxide from the atmosphere, making them a closed-carbon cycle fuel. This means they do not introduce new carbon into the environment, unlike fossil fuels. The production process involves several key steps.

- Electrolysis – Water is split into hydrogen and oxygen using electricity, ideally sourced from renewable energy. This step is critical to ensuring the process remains carbon-neutral.

- Carbon Capture – Direct Air Capture (DAC) technology extracts carbon dioxide from the atmosphere using a chemical process. Sodium hydroxide is one such adsorbent that enables the capture of CO₂.

- Reverse Water-Gas Shift Reaction – The captured carbon dioxide is combined with hydrogen in a catalytic reaction to produce carbon monoxide and water. This reaction can also be achieved through electrolysis.

- Syngas Formation and Fischer-Tropsch Synthesis – Carbon monoxide and additional hydrogen are combined to form syngas, which is then processed through the Fischer-Tropsch reaction, a method originally developed in 1925 by German scientists Franz Fischer and Hans Tropsch. This high-temperature, high-pressure reaction uses iron or cobalt catalysts to bond carbon atoms into hydrocarbons, producing liquid fuel.

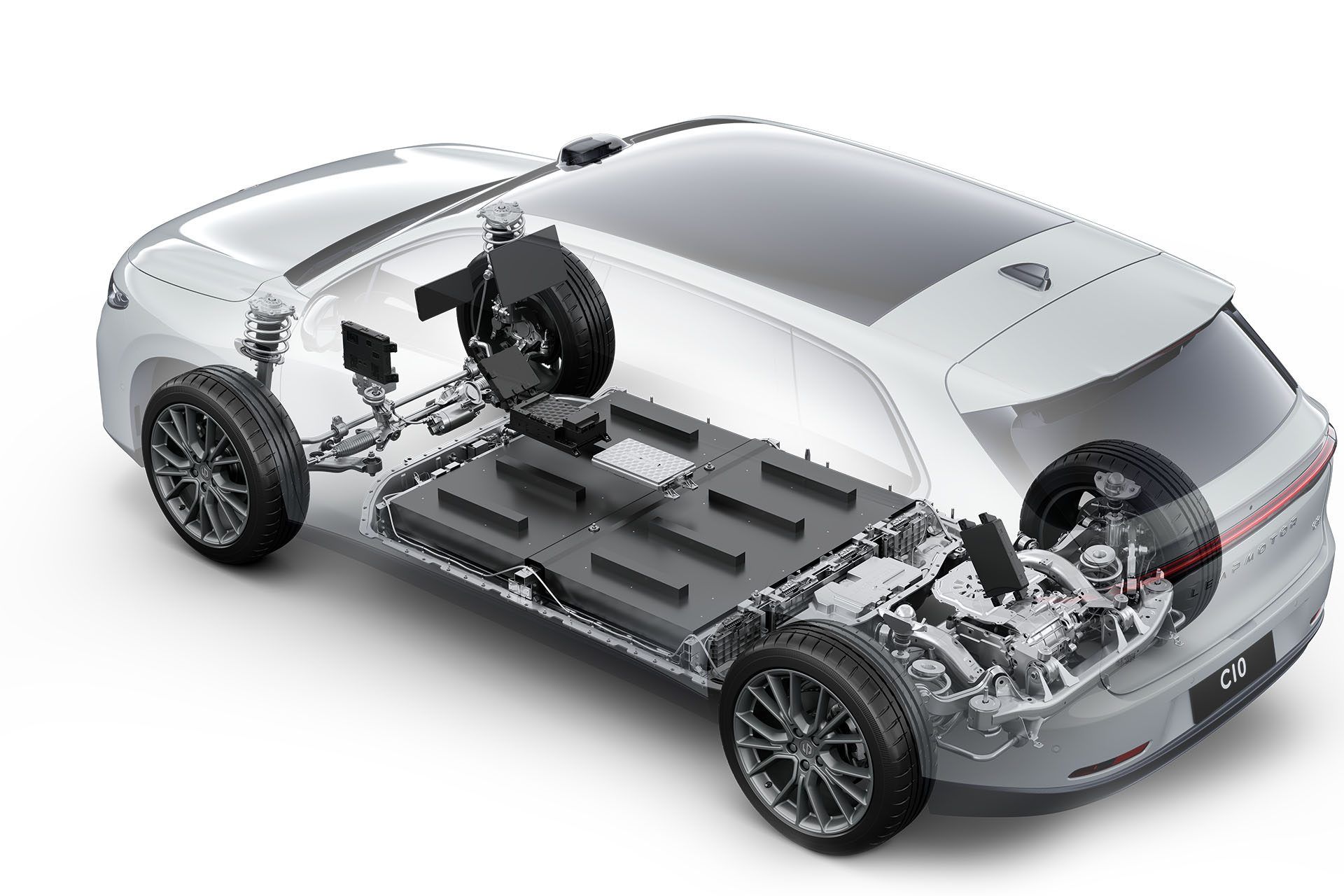

From approximately 1.46kg of water and 3.07kg of carbon dioxide, 1kg of hydrocarbon fuel and 3.53kg of oxygen can be produced. The resulting fuel is chemically similar to traditional petrol or diesel, meaning it can be used in existing internal combustion engines without modification.

Historical Context and Challenges

The concept of synthetic fuels is not new. During World War II, Germany produced about 9% of its fuel supply using the Fischer-Tropsch process due to a shortage of natural crude oil. However, at the time, the process was energy-intensive and expensive, limiting its widespread adoption. These same challenges persist today.

The primary hurdle for e-fuels is scalability and energy efficiency. The process requires significant amounts of electricity, and if this electricity comes from fossil-fuel-based sources, the carbon savings could be negated. Therefore, the viability of e-fuels depends on using renewable energy for production. While Formula 1 teams can be supplied with enough synthetic fuel, the real question is whether e-fuels can be mass-produced efficiently for the broader automotive market.

For Australian automotive professionals, particularly members of the Institute of Automotive Mechanical Engineers (IAME), the rise of e-fuels represents both an opportunity and a challenge. The Australian government has committed to reducing carbon emissions, and while EVs are part of that strategy, the existing fleet of internal combustion engine (ICE) vehicles will remain on the road for decades. E-fuels provide a solution that allows these vehicles to operate sustainably without requiring costly infrastructure overhauls.

For IAME members involved in mechanical engineering, servicing, and tuning, e-fuels could become a major market in the coming years. Workshops may need to adapt to servicing engines optimised for synthetic fuels, and performance tuners could see new opportunities in fuel mapping and combustion efficiency improvements. The ability to offer low-emission, carbon-neutral fuels may become an attractive selling point for workshops and mechanics looking to future-proof their businesses.

The transition to synthetic fuels will depend on government policy, investment in renewable energy, and advancements in production efficiency. Motorsport has long been a testing ground for cutting-edge technologies that eventually make their way into commercial vehicles—disc brakes, turbochargers, and hybrid powertrains all originated from high-performance racing. E-fuels could follow the same path, providing a bridge between today’s petrol and diesel engines and the net-zero future.

As Australia’s automotive industry prepares for a carbon-neutral future, IAME members should stay informed about developments in synthetic fuels. Whether through training programs, industry partnerships, or advocacy for policy incentives, the IAME has a critical role to play in shaping how e-fuels fit into Australia’s automotive landscape.

The next few years will be pivotal. The technology is here—the challenge now is making it economically and logistically viable for widespread adoption. And as always, innovation starts with those who understand the mechanics behind the machines.