OUR PURPOSE

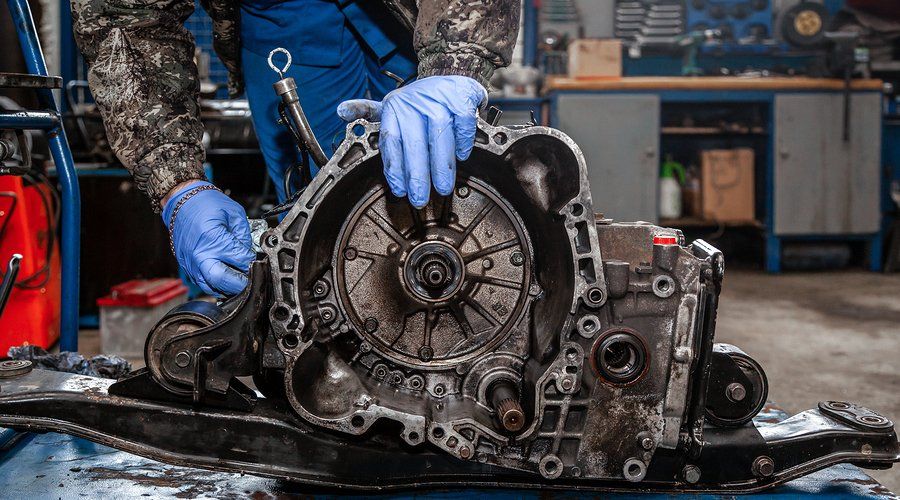

The IAME aims to assist members by providing industry relevant Automotive Training, Branch Information sessions, Seminars, as well as Auditing, Assessing and Consulting Services.

Members also benefit from technology updates provided via our Exclusive Member Online Portal and various media outlets, covering a vast array of technical as well as general topics.

The IAME Print Shop provides a full range of printing products, both for personal or business purposes. Other products include a range of Automotive Tools, Equipment, Books and Workshop Supplies.

Members views are represented through the involvement of IAME Staff on many committees at decision making levels.

THE INSTITUTE OF AUTOMOTIVE MECHANICAL ENGINEERS

THE IAME WOULD LIKE TO WELCOME YOU AS A MEMBER.

JOIN TODAY!

Members of the IAME are drawn from all avenues of the Automotive Industry.

The following established Divisions are constantly monitored so that any change to the Industry is acknowledged and provision made within the Institute to provide relevant benefits.

LATEST: ARTICLES / NEWS / EVENTS